Epsilon Kitchen is a turnkey equipment manufacturing company, committed to providing custom solutions to every requirement of the Hospitality Industry. Our Focus is on design, value engineering & energy saving solutions for our broad spectrum of clients. Complementing our full line of custom fabricated equipment is our Bakery Line & Imported equipment solutions to match every budget, backed up by our technicians trained by manufactures in India & abroad. We continuously work hard on improving our designs, production process & endeavor to raise the bar beyond accepted international safety standards.

Our Equipment is fabricated by adapting the European hygienic standards to make your kitchen equipment safe and functional keeping up to demanding food industry standards.

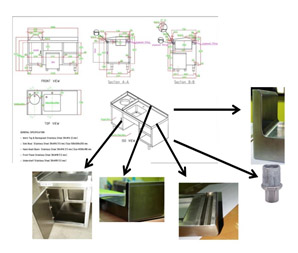

We pride our self’s in being one of the first manufactures to add aesthetics and functionality into our designs , our monoblock systems are manufactured to suit all types of kitchens , from Bulk cooking staff canteens to open kitchens of concept restaurants, both single block & cantilever type.

The cooking elements are inserted into the unit in a perfectly sealed way, without visible gaskets or sealants.

Our Monoblock systems incorporate all types of cooking from Chinese Range; Gas operated dim sum steamers to the complete Indian & European cooking line equipment.

Some of the features incorporated in our design are ;

Long-lasting electrical and electronic components, protected by air filters and with an embedded forced cooling system.

Oversized electronic components to increase reliability and avoid the aging of electronic components.

No visible grids on the kitchen side structure.

Simple repairs and easy accessibility for maintenance.

A clean and minimal design with a unique and modern style, for a safer and more ergonomic kitchen, without protrusions and with integrated knobs and controls.

A kitchen without unsightly openings for better hygiene and safer cleaning operations.

Electronic temperature sensors for the control of hot elements, for

protection in case of accidental contacts.

Overheating control sensors.

Pasta cookers and fryers with large rounded corners.

Self-draining pasta cooker tanks.

Thanks to the reduction of heat dispersed in the environment, the radiation of heat on people is very little and the temperature in the kitchen decreases by about 15/20 °C . This leads reduction from 30% to 60%* in aspirations and consequent reductions in air currents. Kitchen workers will no longer be impregnated with fats and volatile unpleasant odors.

Having no more open flames and unburned gases that burn oxygen inside the kitchen, it will be much healthier and less dangerous due to injured burns.

The creation of a comfortable working environment results in higher staff commitment and performance with reduced turn-over typical of seasonal services.

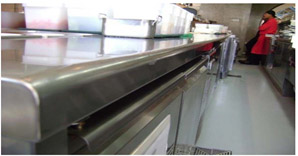

Our Kitchen ranges offer high performance cooking with many versatile features valuable for any professional kitchen. All models come with Gas & Electric Oven options. All input materials used are of the highest quality and used keeping replacement availability in mind. Available in the following Configurations

Our Kitchen ranges offer high performance cooking with many versatile features valuable for any professional kitchen. All models come with Gas & Electric Oven options. All input materials used are of the highest quality and used keeping replacement availability in mind. Available in the following Configurations. Our Bain Maries are designed to ensure better efficiency & lower running costs, and are available in many sizes with a variety of standard and optional features. Dual heaters for trouble free operation. Better input material ensuring longer life & trouble free operation. Available in all configurations & sizes including Table top to free standing models with and without glass.

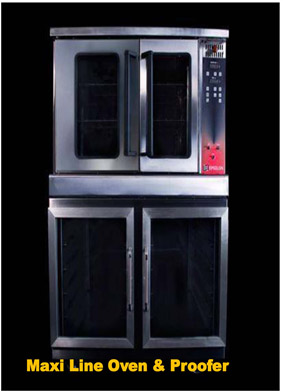

Heavy duty, simultaneously-opening compartment doors, with extra-large double pane tempered glass windows

Electric Half Size Convection Oven

The outer casing is manufactured from easy-to clean, polished stainless steel AISI 304. The canopy comprises connections and damper. The joints of the lower edges are fully welded and polished to ensure water tightness. A collection tray or a drain tap is fitted into the grease drain channel in order to enable removal of the grease and dirt extracted by the filters.

Each canopy shall be provided with a fluorescent light fixture providing an average luminance of approximately 500 lux at the work surfaces of the cooking appliances. The light fitting shall be suitable for a single-phase 230-VAC power supply and available both in White Light & Day Light options. The ballast and capacitor shall be located within the light fitting housing. The light fittings shall be hinged to allow access to the canopy roof. A core electric cable (3x1mm²) connecting the light fitting to the junction box is also provided.

The grease filters shall be supplied in modular size 500 x 500 mm and shall be removable via two folding handles. Our Double Plenum Hoods prevent spreading of the heat and impurities produced by cooking into the work area. The hoods deliver a small air jet that pushes the rising thermal current to the grease filters. These hoods are 30% more efficient, due to their lower air flow rates, which add up to direct savings on running and initial costs.

Our slip resistant metal floor drain covers are designed for applications where durability and safety are critical. Many food processing plants utilize our stainless steel drain covers to keep workers safe in a wet and slippery work environment.

Our Grease Traps are muti chamber ensuring proper function even in the most demanding environments & is an approved design at all Indian Airports & Malls.

An efficient bar layout helps the bar tender to be more productive by keeping everything with reach and avoiding waste motion. An efficient bar layout also provides ample storage for juices, ice, and blender’s tec. At epsilon we ensure all components of your Bar incorporate all the above.